The adjustment of China's economic structure has increased the demand for machine tools

With the steady development of the national economy, Chinese positive efforts to promote economic restructuring and change the mode of development, key areas and key projects of high-end CNC machine tools, cutting tools, precision measuring instrument, the demand of market space. Below some key user profession development as well as to the machine tool demand, and everybody carries on the simple exchange.

aviation industry

China's aviation industry has achieved rapid development, technological progress is obvious. Commercial Aircraft Corporation of China was established in 2008, officially launched the big aircraft project. At present, the large aircraft project prototype C919 has been developed, and participated in the 2010 Zhuhai Expo, 2011 Chinese aerospace aviation and Aerospace Exhibition in Paris, C919 is expected to be in 2014 first flight, 2016 to obtain a certificate of airworthiness and put on the market. The success of the C919 will create an emerging civil aviation industry in China, giving new opportunities to China's machine tool market. The total investment of large aircraft projects will reach 200 billion yuan, of which the investment in manufacturing capacity will reach 30 billion yuan. The aviation industry requires a high level of machine tools, covering almost all the achievements of modern machine tools, including high-speed, precision, efficient, composite CNC machine tools, five axis machining centers and other key manufacturing equipment, as well as modern efficient cutting tools.

Shipbuilding Industry

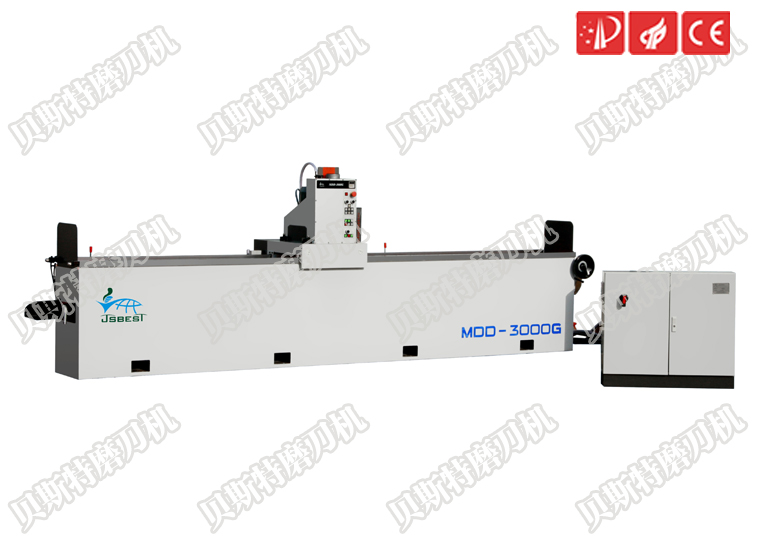

China is one of the most influential shipbuilding country in the world in 2010, the steady growth of China shipbuilding industry, continue to expand the international market share, shipbuilding capacity record reached 65 million 600 thousand deadweight tons, an increase of 54.6%, new orders 75 million 230 thousand deadweight tons. In 2011 1-6, shipbuilding finished 30 million 920 thousand tons, new orders 21 million 600 thousand deadweight tons. The rapid development of China's shipbuilding industry, while facing fierce competition, bear the pressure to improve shipbuilding efficiency and reduce shipbuilding costs. To 2015, to form the development and construction of high technology and high value-added ships of the annual shipbuilding capacity of 28 million deadweight tons, the annual output of 22 million tons deadweight; marine low speed diesel engine, the annual production capacity reached 6 million kilowatts and 1200 units. This brings new opportunities to the machine tool industry, shipbuilding enterprises to set up modern shipbuilding mode, need heavy and super heavy Longmen milling machine, CNC boring and milling machine, CNC boring milling machine five, crankshaft milling center, and plate processing equipment of large crankshaft grinder and other large high-grade heavy-duty CNC machine tools.

automotive industry

China's automobile industry has been growing rapidly for many years, and China has developed into the world's largest automobile producer and the world's largest auto consumer market. In 2010, China's auto production and sales were more than 18 million vehicles, an increase of more than 32%. In 2011, 1-6 months, China's auto production and sales were more than 9 million vehicles, is expected in 2011 China's auto industry will continue to grow. Statistics show that, by 2015, the top 10 enterprises in China's auto industry, planning annual output will reach about 32 million 500 thousand. This means that the next few years, China's auto industry will invest huge sums of money to expand production capacity, transformation of existing automotive production lines. The automotive industry has been the most important user in the machine tool industry, and the development of China's automobile industry is pregnant with a huge market of machine tools. Automobile manufacturing has the characteristics of mass production, and requires a large number of high-speed, efficient and high reliability CNC machine tools.

Power industry

The shortage of energy has been a bottleneck restricting the development of China's national economy. In order to maintain the sustainable development of China economy, change the mode of economic development, Chinese power industry will implement the diversification of energy supply strategy, will be efficient, clean energy as a key development target, single energy to change the over reliance on coal situation. According to the plan, by 2015, China's non fossil energy consumption accounts for more than 11% of the primary energy consumption. In 2020, the proportion of non fossil energy consumption should be 15% of the primary energy consumption. To this end, in 12th Five-Year, the national power industry investment scale reached 5 trillion and 300 billion yuan, of which 2 trillion and 750 billion yuan power investment, power grid investment 2 trillion and 550 billion yuan. The development of electric power industry, need a large number of high reliability, large size, high stiffness of CNC machine tools, such as heavy-duty CNC boring and milling machine, Longmen Heavy CNC Floor Boring and milling machine, heavy-duty horizontal lathe, machining machine tool and special machine tools such as Ye Gencao.

These users are a key China machine tool market, demand for machine tools is large, in addition to agricultural machinery, engineering machinery, textile machinery, railway and other industries in adjusting the structure, change the mode of development, technological upgrading of industry, there are a lot of demand for machine tool products, and the demand to high-grade the development trend is very obvious, is expected to Chinese high-end machine tool imports will still maintain growth momentum.